We engage in the manufacture of inorganic chemistry products with plants spread across four continents – America, Europe, Africa and Asia. We are the world’s third-largest Soda Ash and India’s leading vacuum evaporated iodised salt producer. Our salt works, spread over 36,000 acres, are the largest in Asia. We produce soda ash using synthetic and natural mining process. Of this, 3/4th capacity consists of natural soda ash allowing us significant cost competiveness.

Customer-centricity, operational excellence and sustainability are the key pillars of our strategies. We are a preferred choice of customers and continue to focus on building and consolidating relationship. Our portfolio comprises differentiated and value-added brands and products meeting the specific customer needs. We lead and succeed in the market through continuous improvement programmes, cost optimisation, and lean and innovative supply chain solutions. Safety is one of our core values as we strive to achieve our target of Zero Harm.

Detergent, Sodium Bicarbonate, Sodium Silicates, other chemicals, dyes and intermediaries

Light Soda Ash, STPP

Float glass - construction and housing, automotive sector, silicates

Container glass - soft drinks, spirits, pharmaceuticals, tableware, glass

Light Soda Ash, STPP

Pharma (US/British/Indian Pharmacopoeia), Food, Animal and poultry feed, Food grade dust, Explosion suppressant, Haemodialysis, Flue Gas Treatment

Pharmakarb, Medikarb, Sodakarb, Alkakarb, Speckarb, Hemokarb, Briskarb

Food processing, industrial salt, de-icing, dairy products, water softening and industrial applications

Edible Salt, Glacia, Granulite (British Salt), Magadi Moore, Nyama and Moore Maziwa

Construction, Pre-cast Pipes, Blocks, etc.

Tata Shudh OPC, Masonry Cement and PPC

Agri Chemicals, Pesticides, Pharma Intermediaries, Fire Retardants, Textile Processing

Liquid Bromine, Caustic Soda

Sodium Silicate, Animal feed additive, Lead processing, Mining applications, Effluent / Flue gas / Compost heap treatment

ZnSpers, Zing C Spl, Zn Coat WD/Znmer

Strong corporate brand and very high image score

World’s – 3rd largest Soda ash manufacturer

Lean supply chain and network of depots, pioneers in bulk movement of soda ash in India

Market leaders in Bicarb and a major player in Soda Ash in India

TCNA has significant market presence in the U.S. and Canada

Market leader in Bicarb and Soda Ash in UK

Strong and Long-standing relationships with Blue chip customers spanning over several decades

High Marketing capability due to partnership with ANSAC

Efficient, cost effective, safe and sustainable

TCE-groundbreaking HR practices to utilise 21st century processes for traditional industries

Use of technology for deeper customer connect and ease of doing business

World’s leading state-of-the-art CHP power plant-Low carbon emissions in UK

Grow volume of current products and strengthen leadership through:

As a step towards circular economy, we established our cement production facility in 1993 to utilise the solid waste generated in the manufacturing of Soda Ash and to realise value from it. Our strategic direction in the business has been to continuously add value to products to meet customer requirements. Subsequently, we expanded our portfolio to Masonry cement, a niche and unique product and OPC cement with high one-day strength.

Continuing this journey forward, we expanded our product offering by launching Tata Shudh PPC Cement in response to the changing customer expectations for blended cements. Made of high-quality fly ash, this cement can be used for all construction applications. With this, our cement portfolio cuts across wide application segments and offers widest range in construction in our core markets of Saurashtra and Kutch.

With rising demand, our PPC cement is gaining increasing acceptability due to its quality and versatility. To serve this growing demand, we have planned to further augment our production capacity by 0.3 MMT by FY 2021-22.

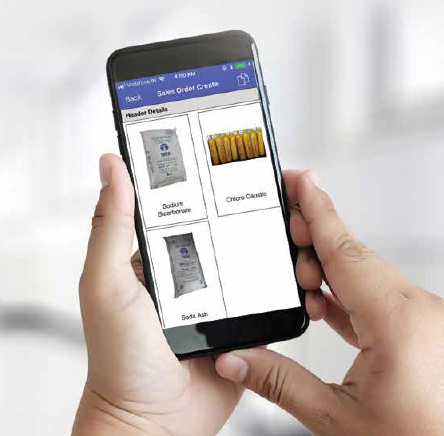

ChemConnect is our cloud-based web application, providing real-time access and services on the go. A one-stop shop solution, it makes available information and data, facilitates transaction tracking and eases conducting business through facilities like order booking, MIS, banking, balance confirmation, complaint management etc.

Launched initially in the B2B context of Indian Chemical operations, ChemConnect today helps serve our customers (business partners) and goes right up to the next tier of our customers’ customers i.e. the end customers. It powers our global chemical operations and remains at the forefront of redefining customer experience. Its success can be gauged from the fact that more than 99% of orders are effortlessly booked by our channel customers through it.

We continue to add more features to make the application more robust. During the year, we completely stabilised customer empowerment and business transparency. We also added online channel finance facility through banks for instant low-cost finance which has been well received by channel partners. It will be instrumental in growing theirs as well as our business.

Two legacy pulverised coal-fired boilers at TCNA, the largest consuming unit that generate most steam to run the facility and generate power, became inefficient. Further, the soot blower cleaning devices in their Ljungström Air Heaters (LAH) were severely clogged with fly ash, restricting the heat transfer and non-utilisation of waste heat which instead rose up the stack. TCNA invested in replacing the LAHs of both these boilers to improve their efficiency and operation. It resulted in the stack temperatures declining from 390o F to 325o F and hence 14,000 tonnes / year of lower coal usage translating into ~US$ 700,000 annual savings. Additionally, it enabled boilers to operate at full production and curbed SO2 emissions by 187 tonnes per year.

From 2021, Tata Chemicals Europe will be making one of the lowest carbon footprint sodium bicarbonate and sodium carbonate products in the world by investing in a carbon capture and utilisation (CCU) technology.

The CCU plant will capture CO2 from the flue gases emitted from its combined heat and power plant (CHP) and transform it into a key raw material for manufacturing sodium bicarbonate, thereby reducing emissions. It will be capable of capturing up to 40,000 tonnes per year of CO2 i.e. ~10% of TCE’s carbon emissions at the CHP plant. It will support the annual manufacture of over 120,000 tonnes of high purity sodium bicarbonate used in haemodialysis, pharmaceuticals, food, animal feed and many other applications.

The project could pave the way for other industrial applications of CO2 capture and is an important step in decarbonising industrial activity. The TCE CCU plant will play a major role in supporting the Government’s recently announced target of net zero carbon emissions by 2050.

Our revenue growth will see good trajectory as we keep commissioning our capex projects.

We would also continue our journey on the path of pioneering and providing thought leadership through introducing first-in-the-market products and services that provide unique solutions and value to our customers. Introduction of sodium bicarbonate brands addressing targeted segments, online ChemConnect to the second-tier customers, instant channel finance through ChemConnect, bulk supplies, introduction bulkers etc. are steps towards this journey.