NATURAL CAPITAL Addressing Environmental Challenges for a Sustainable World

With sustainability at the core of our strategy, we are strengthening our long-term resilience by undertaking pioneering initiatives that contribute to a thriving world, communities and enterprise. We have aligned our sustainability goals with Responsible Care, CORE and UN SDGs guidelines to ensure maximum impact.

Sustainability priorities

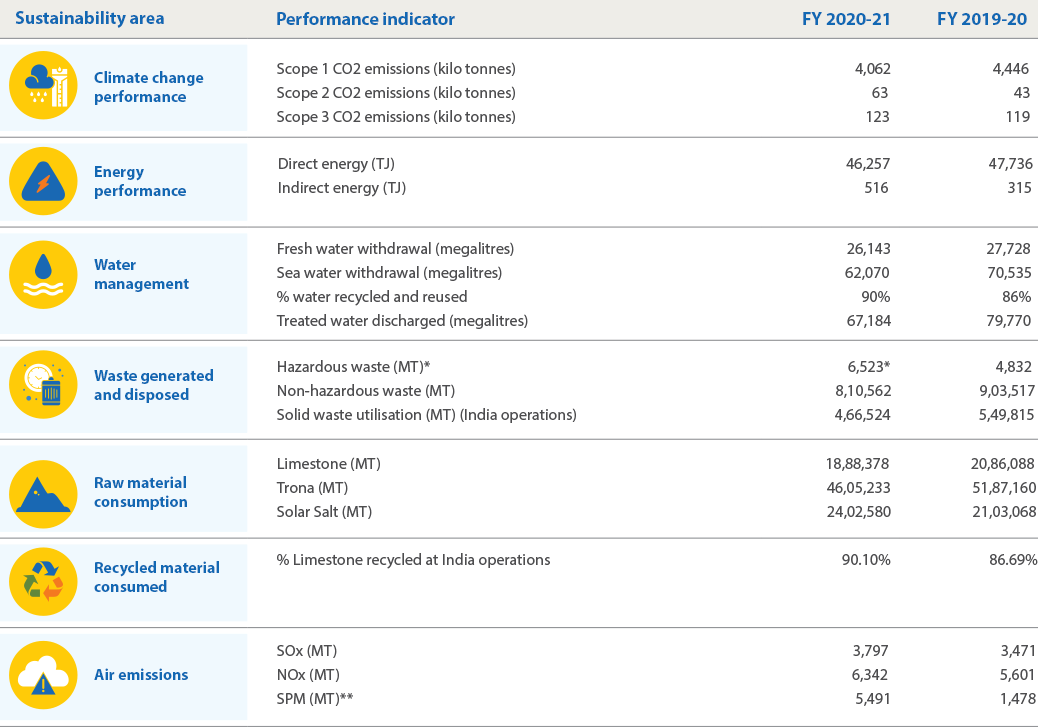

- Carbon abatement: Fuel change, renewable energy & carbon capture

- Circular economy: Waste management, recycle and reuse

- Biodiversity: Preserve natural capital, conservation and restoration of biodiversity

Our sustainability focus areas

Growing shared values

- Long-term inclusive growth and relationship with shareholders

- Enhancing portfolio of value-added, green and patented products (i.e. Sodium Bicarbonate, Highly Dispersible Silica)

- Accelerated digital adoption and use of data analytics to enhance operational efficiency

- Shifting from solvent-based to more sustainable water-based formulations

Promoting low-carbon economy

- Carbon abatement study to reduce absolute carbon reduction and achieve net zero carbon

- Energy management through energy audits, improvement in operational efficiency and shift to renewable energy (Mambattu plant added solar power capacity)

- Initiating carbon capture and conversion to usable liquid form at TCE to produce carbon neutral Sodium Bicarbonate

Minimising environment footprint

- SBTi commitment

- Conducted climate change risk assessment and waste mapping study

- Promoting smart agriculture

- Emphasis on continuous improvement in the recycle of water and waste materials

- Transitioning to clean fuels and technology and higher use of alternate materials (i.e. plastic waste for cement)

- Continuous performance monitoring with air emissions monitoring systems and pilot concentrator

- Responsible Care and CORE certified operations (India)

Creating sustainable societies

- Extensive tree planation drive across 500 acres (target of 3 million tree plantation by 2030)

- ‘Prakriti’ Mitra-Sakhi Mandals

- Promoting species conservation and strengthening biodiversity: restoration and conservation of coral reefs (2,000 m2 area coverage)