Digitalising manufacturing at Mithapur plant

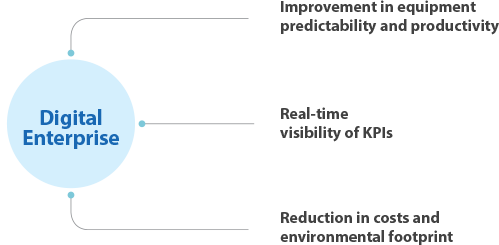

The Mithapur plant has embarked on a journey to become a world-class, smart factory. It is implementing the Digital Enterprise – the connected plant concept – in collaboration with a globally reputed organisation. With this, systems, processes and functions are being connected using ‘data’ as an enabler by employing world-class technologies such as Analytics, IIoT, AI/ML algorithms, etc.

The system integrates data from multiple applications (distributed control / production systems / ERP / supply chain management / customer relationship management systems) into integrated analytics dashboards for real-time monitoring of plant operations, supply chain optimisation and inventory control.

IIoT application

IIoT application is being implemented in carbonation towers and boilers. This comprises creating digital twin of the process using AI/ML techniques.

Benefit:

Prescriptive analytics and generation of online advisories to run the operations more efficiently

Predictive analytics

Benefit:

Better equipment health by reducing unplanned downtime and enabling a shift to predictive maintenance

Satellite image analytics

Benefit:

Improving predictability and efficiency of solar Salt operations

Status:

Automation of all major critical operations in Soda Ash and Salt manufacturing and power plant operations is either completed or under different stages of implementation.